The vessels in the brewery needed some modification to function in a multi-vessel system. A 60L pot that had been a boil kettle became the new mash tun, including a false bottom. A new 80L pot now functions as the boil kettle, and a round cooler previously used as a mash tun is now the hot liquor tank.

As this is an all-electric build, both the kettle and hot liquor tank needed heating elements mounted. Both also gained a drain port and a sight glass.

Hot Liquor Tank

Materials

- 1500W Element - Amazon = $20

- Weldless electrical enclosure - EWL1 @ BrewHardware = $24

- ½” ball valve - 3PBV @ BrewHardware = $18

- ½” bulkhead, long - VB2 @ BrewHardware = $15

- ½” F cam-lock - BrewHardware = $4

- Level gauge - LPC @ BrewHardware = $28

Build

This build started with a Rubbermaid cooler previously used as a mash tun. For mashing, I had replaced the original plastic spigot with a 3/8” ball valve and barb, but this was too small for a hot liquor tank. This required enlarging the original hole with a step bit. With that in place, the long bulkhead fit nicely and clamped down on the vessel wall.

The other bits – the level gauge and the element – were a little more complicated. The wall of the cooler is thick, with crumbly foam insulation in the middle. Both pieces seal against the inside of the cooler’s inner wall, but require a larger hole through the insulation and outer wall.

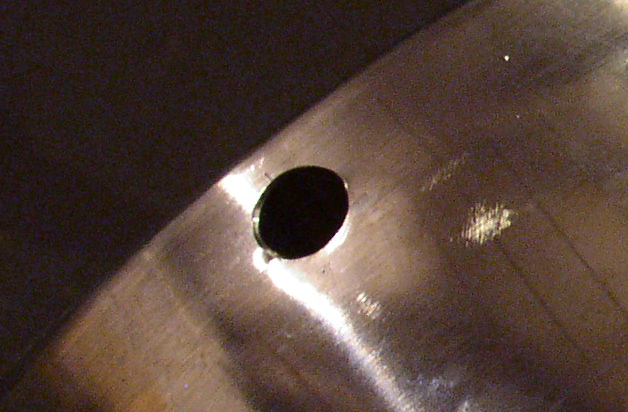

The instructions on BrewHardware give the detailed measurements. The level gauge only required regular drill bits, and the hole is visible in the picture above.

The outside hole to contain the electrical enclosure required the services of a hole saw, with some adjustments by Dremel to get a good fit.

Wiring the electrical enclosure is difficult. Stranded 10-gauge wire is bulky and doesn’t like to bend, but the enclosure requires the ground to go to the outer piece, while the hot and neutral go to the element itself, mounted to the cooler. Securing all of this required some fiddling with needle-nose pliers and some care in screwing the outer and inner pieces of the enclosure together.

Here’s the final hot liquor tank. This tank sits on the upper shelf of the brew stand and drains sideways to the mash tun. The power cable runs diagonally to the back of the stand, while the level gauge faces diagonally to the front where it can be read but not bumped.

Boil Kettle

Materials

- Camco 02962/02963 5500W 240V Screw-In Lime Life Ripple Water Heater Element, Ultra Low Watt Density - $26

- Weldless electrical enclosure - BrewHardware EWL1 = $24

- Stainless Steel 1” Female Hex Locknut - Amazon = $7

- Weldless bulkhead - WLPBULKHEAD 1 @ BrewHardware = $14

- ½” ball valve - 3PBV @ BrewHardware = $18

- ½” F cam-lock - BrewHardware = $4

- Level gauge - LP @ BrewHardware = $27

Build

Modifications to the kettle were pretty simple: drill three holes, and add the corresponding components. The bulkhead is oriented at the front of the vessel, with the level gauge about 45° to the right. The element is mounted 45° from the back, so that the enclosure and cable don’t bump against the wall behind hte stand.

Drilling stainless is exceedingly difficult. I own a decent power drill with an extra handle on it, and I purchased a brand-new step bit. I read up on drilling and learned to be careful of work-hardening, and to use a lubricant. Sources suggested drilling a pilot hole with a tungsten or carbon steel bit. I did all of these things, and still made no progress. I had a beautiful new pot with a few tiny dents where I wanted holes.

After a few frustrating evenings marring my expensive new toy, I took the pot to Ryan Hope, who had already successfully drilled his equipment. He managed to slice right through the pot with almost no trouble. I credit his talent and experience and a drill with better-placed handles allowing him to exert more force.

The weldless electrical enclosure from BrewHardware is almost identical to that for the hot liquor tank.

The weldless fittings attached beautifully to the pot, once the holes were in place. Nothing has leaked! Here’s a shot into the kettle as it was heating. While it looks like the contents are about to come to a boil, the water here is still fairly cool. The pre-boil convection around the element is actually very poor, so the water near the element will get hot without mixing well with the other water. Once the boil begins in earnest, the contents mix nicely.